Whether it is new energy vehicles or energy storage equipment, one of the most important key components is the battery, and one of the challenges of the battery industry in recent years is to increase energy density and pursue safer ways, whether it is trying new positive and negative electrode materials; or increase the proportion of nickel in nickel-manganese-cobalt (NMC) ternary batteries; There are also people who are committed to developing technologies different from traditional lithium batteries, such as hydrogen energy vehicles that use hydrogen fuel cells. Solid-state batteries are considered the next generation of battery technology.

1. What is a solid-state battery?

What kind of technology is an all-solid-state battery?

If in layman’s terms, an all-solid-state battery is a battery that has no gas or liquid in it, and all materials exist in solid-state form.

Considering that the most common battery in people’s daily life is lithium-ion batteries, we will default to “all-solid-state lithium-ion batteries” as a representative of all-solid-state batteries (temporarily ignoring new batteries such as all-solid-state lithium-sulfur).

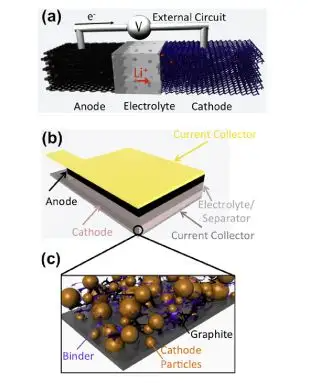

In general, lithium-ion batteries are mainly composed of positive electrode, negative electrode, separator, electrolyte, structural shell and other parts, in which the electrolyte enables current to be conducted in the form of ions inside the battery.

Electrolyte technology is one of the core technologies of lithium batteries, and it is also a highly profitable component of the battery industry.

Among them, Li+ (lithium ions) is in the internal circuit and conducts through the electrolyte

However, some lithium batteries will bulge after a long time, and in more extreme small probability events, some may even be dangerous (such as the recent battery explosion of the twisting car, which has led to comprehensive difficulties for related manufacturers and battery companies).

IN ADDITION, IN GENERAL, THE OPERATING TEMPERATURE RANGE OF LITHIUM-ION BATTERIES IS LIMITED, AND THE LIFE WILL BE SHARPLY SHORTENED AT A HIGH TEMPERATURE OF MORE THAN 40 DEGREES, AND THERE WILL BE GREAT PROBLEMS WITH SAFETY PERFORMANCE (SO TESLA MODEL S WILL HAVE A STRICT BATTERY TEMPERATURE CONTROL SYSTEM, WHICH IS FOR THIS).

In fact, several of the above safety issues are directly related to the electrolyte of the organic system we now use in batteries.

In order to solve the battery safety problem and improve the energy density, the scientific research community and industry are currently developing and producing all-solid-state batteries, that is, replacing the separator and electrolyte of traditional lithium-ion batteries with solid-state electrolyte materials.

So, compared with the most common ordinary lithium-ion batteries in our lives, what are the main advantages of all-solid-state batteries?

2. Advantages of solid-state batteries?

advantages1: thin (small size)

In fact, volumetric energy density is a very important parameter for batteries, if in terms of application areas, the requirements from high to low are consumer electronics “home electric vehicles” electric buses.

If in layman’s terms, it is the volume energy density is high, so the same mass of the battery can do smaller volume.

The available space in electronic products is often very limited, many products (such as mobile phones, tablet computers) have nearly 1/3 of the volume and quality has been occupied by the battery, and in the majority of manufacturers and consumers want to further improve the capacity of the battery (increase battery life) and compression volume (portable beautiful and easy to design) requirements, high-pressure, the highest volume energy density lithium cobalt oxide (LCO) battery is still the mainstream product.

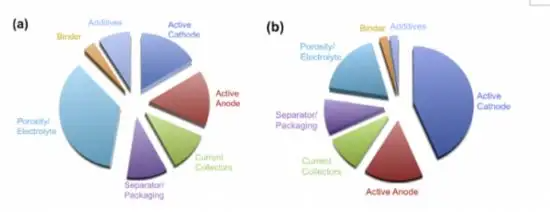

In traditional lithium-ion batteries, separators and electrolytes are required, which together account for nearly 40% of the volume and 25% of the mass of the battery.

And if they are replaced with solid electrolytes (mainly organic and inorganic ceramic materials), the distance between the positive and negative electrodes (traditionally filled by the separator electrolyte, now filled by the solid electrolyte) can be shortened to even a few to a dozen microns, so that the thickness of the battery can be greatly reduced – so all-solid-state battery technology is the only way to miniaturize and thin film batteries.

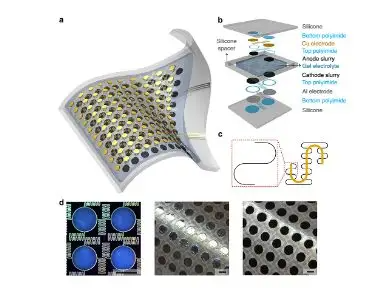

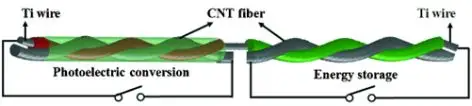

Not only that, many all-solid-state batteries prepared by physical/chemical vapor deposition (PVD/CVD) may have an overall thickness of only a few tens of microns, so they can be made into very small power devices and integrated into the MEMS (microelectromechanical systems) field.

Being able to make a very small battery is also a major feature of all-solid-state battery technology, which can facilitate the battery to adapt to the application of various new small-size intelligent electronic devices, and at this point, traditional lithium-ion battery technology is difficult to achieve.

(The current proportion of (a) volume and (b) mass of each component of lithium-ion batteries)

At present, a key obstacle to the practical use of many nanomaterials is that the specific surface area is large and the bulk density is too low, resulting in products based on these materials, often occupying too large a volume under the same mass, that is, the volumetric energy density is low, which is completely unable to meet the requirements of general industrial products.

Therefore, the current nano (battery) material scientific research often chooses not to report this parameter, and the reason is not difficult to understand.

advantage2: flexible prospects

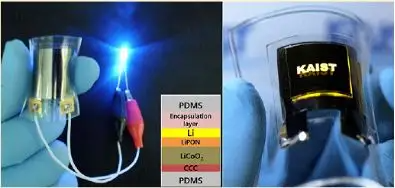

All-solid-state batteries can be further optimized to become flexible batteries, bringing more functions and experiences.

In fact, even brittle ceramic materials can often be bent after the thickness is thin to the millimeter level, and the material will become flexible.

Correspondingly, the flexibility of all-solid-state batteries will also be significantly improved after thinning, and by using appropriate packaging materials (not a rigid shell), the battery can withstand hundreds to thousands of bends to ensure that the performance is basically not attenuated.

In fact, flexible electronic devices represented by various wearable devices are an important direction for the development of the next generation of electronic products, and this requires that the components in the product also need to be flexible, so flexible all-solid-state batteries are very promising tomorrow’s stars in scientific research and industry.

(Flexible all-solid-state battery with typical stacked structure prepared by KAIST in Korea)

Not only that, the potential of functionalized all-solid-state batteries is far more than the above flexible batteries, after the optimization of the battery material structure can be made into transparent batteries, or stretchable batteries with a stretch range of up to 300%, or power generation-storage integration devices that can be integrated with photovoltaic devices, etc. – all-solid-state batteries mean that there are many innovative application prospects in the function, and the imagination of researchers and engineers will bring us more and more surprises in this regard.

Advantage3: more secure

As an energy storage device, virtually all batteries cannot be inherently thermodynamically safe.

However, the factors that determine the true safety of batteries in practical applications are many, including the characteristics of the battery’s electrode material, the nature of the electrolyte, and the battery management system in electronic products.

At present, the safety of general commercial lithium-ion battery is the focus of everyone’s concern, and it should be a more appropriate evaluation to evaluate the safety of the current battery with “less than ideal” here.

Advantage 4: Light (high energy density)

After the use of all-solid-state electrolyte, the applicable material system of lithium-ion batteries will also change, the core of which is that it is not necessary to use lithium-embedded graphite anodes, but directly use lithium metal as the negative electrode, which can significantly reduce the amount of negative electrode materials, so that the energy density of the entire battery has been significantly improved.

In addition, many new high-performance electrode materials may not have had good compatibility with existing electrolyte systems before, but this problem can be alleviated after using all-solid electrolytes.

Considering the above two factors, the energy density of all-solid-state batteries can be greatly improved compared with general lithium-ion batteries: now in many laboratories, it is possible to trial produce all-solid-state batteries with an energy density of 300-400Wh/kg on a small scale (general lithium-ion batteries are 100-220Wh/kg).

From the data of energy density, perhaps all-solid-state batteries really have hope to upgrade our lives from “one charge a day” to “one charge in two days”.

3. Technical circuit of solid-state battery?

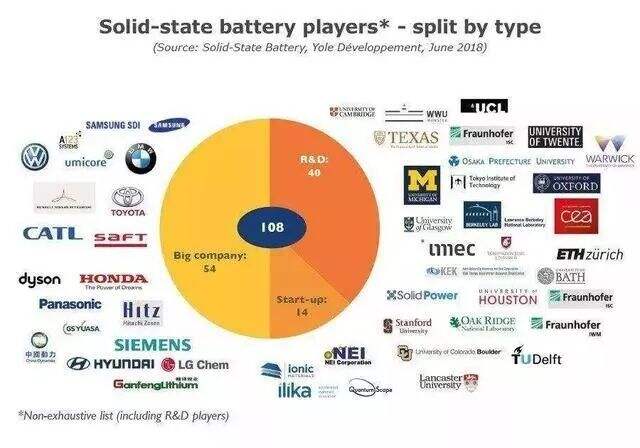

There are different technical routes in the field of solid-state batteries, and solid electrolytes can be roughly divided into three categories: inorganic electrolytes, solid polymer electrolytes (SPE, Solid Polymer Electrolyte), and composite electrolytes. At present, many companies have invested in research materials including solid polymers, sulfides, oxides, thin films, etc. For example, Dyson, Apple’s respective acquisition of solid-state battery factories Sakti3 and Infinite Power Solutions, are film-based, but the process is complex, mass production is difficult, the previous market reported that Dyson, Apple intends to give up, so the current stage of development is not clear, and Toyota, Panasonic (Panasonic), Samsung, BMW, CATL into sulfide electrolytes, Huineng and Sony are focused on oxides.

Apple has been actively deploying patents for solid-state batteries and charging technology since 2012, and acquired Infinite Power Solutions in 2013. In the past two or three years, the news of the layout of solid-state batteries by automobile factories has surfaced significantly, such as Toyota’s announcement that it will sell electric vehicles equipped with solid-state batteries in 2022. In addition, Volkswagen invested in QuantumScape, a solid-state battery startup co-founded by MIT Technology Review TR35 young entrepreneur Jagdeep Singh, and increased its investment in June last year and obtained a director of QuantumScape, which is expected to establish a solid-state lithium battery production line in 2025.

In the past, Japan, a major battery country, has shifted its research focus to solid-state batteries after abandoning lithium batteries, and the Japan Science and Technology Agency (JST) and Japan’s New Energy Industry Technology Development Agency (NEDO) are actively promoting, and these dynamics have made the outside world pay attention to this technology.

4. Technical bottleneck of solid-state batteries?

At present, many battery and automobile manufacturers, including South Korea’s Samsung, Japan’s Toyota and China’s Ningde era, have increased investment in solid-state battery research and development, and some batteries have entered the loading test stage. Although the prospects are promising, due to various problems in technology and technology, the road to the development of solid-state batteries is by no means smooth.

First of all, there is a lack of efficient electrolyte material systems. At present, solid-state battery materials are developing rapidly, but comprehensive applications are relatively lacking.

As the core material of solid-state batteries, there has been a breakthrough in the single index of solid-state lithium-ion conductors, but the comprehensive performance cannot meet the needs of large-scale energy storage. The solid-state electrolytes used in today’s solid-state batteries generally have performance shortcomings, and there is still a big gap between them and the requirements of high-performance lithium-ion battery systems.

(1) The interface processing of solid electrolyte and electrode is also a major problem faced by solid-state batteries.

In the solid electrolyte, the lithium ion transmission impedance is large, the rigid interface contact area with the electrode is small, and the change of electrolyte volume during the charging and discharging process is easy to destroy the stability of the interface.

(2) In solid-state lithium batteries, in addition to the interface between the electrolyte and the electrode, there is also a complex multi-level interface inside the electrode, and factors such as electrochemistry and deformation will cause contact failure to affect battery performance.

Thirdly, the unsatisfactory stability during long-term use is also the bottleneck in the development of long-life energy storage solid-state batteries. The structure and interface of solid-state batteries will degrade with time during service, but the influence mechanism of degradation on the comprehensive performance of batteries is not clear, and it is difficult to achieve long-term applications.

Therefore, the construction of high-performance solid-state batteries needs to start from two aspects, one is to build a high-performance solid-state electrolyte, and the other is to improve the compatibility and stability of the interface.